It’s safe to say that a Gas Chromatograph is one of the most important tools one will see in an analytical chemistry laboratory. Chromatographs are the workhorses of the analytical trade. When it comes to separating, analyzing, verifying purity, or determining concentrations of various chemical concoctions, the “GC” as it is commonly known, can provide a quick, accurate, and repeatable result for a large cross-section of known compounds. Of course, to have precision in analyzing means all the components in the system must work as expected. A clean ‘column,’ appropriate for the substances being separated, a properly prepared sample, diligent injection methodology, and a stable mass flow rate of the inert carrier gas are all required.

Basically, a modern gas chromatograph is designed to take a sample in the form of a ‘slug’ and pass it through a long ‘column’, as carried by a steady flow of inert gas. While the sample moves through the column in a computer-controlled oven, it’s heated to various temperatures, and its output is fed to the detector array. The sample and carrier gas are eventually vented out as waste.

The key measurement function of the GC is centered on timing. As the components of the sample are separated in the column, they emerge at different times and in rising and then falling intensities. The detector simply plots the peaks against time (retention Rt) and strength (peak area). Based on known chemistry, the components and concentrations of the original sample can be determined with amazing accuracy.

Misnomers and misconceptions

![]() If you’re unfamiliar with how a gas chromatograph works, let’s dispel a couple of misnomers and incongruities. First, there is no traditional vertical ‘column’ inside the GC! (The decades old classic ‘column chromatography’ process does in fact use an actual glass tube, up to several feet tall. The column effects the purification of individual chemicals through a powder or slurry, using the principals of partition equilibrium.) Although the over-arching concepts are very similar, the modern GC’s column is now a very thin, coiled capillary tube. These fine quartz or fused silica tubes have only 0.1 to 0.53 millimeter internal diameters, but are cut to 12 to 100 meters in overall length! Modern capillary tube columns are internally coated with a thermally stable, high molecular weight polymer. This extremely thin polymer layer (0.1 – 10 thousandths of a millimeter) is referred to as the ‘Stationary Phase’.

If you’re unfamiliar with how a gas chromatograph works, let’s dispel a couple of misnomers and incongruities. First, there is no traditional vertical ‘column’ inside the GC! (The decades old classic ‘column chromatography’ process does in fact use an actual glass tube, up to several feet tall. The column effects the purification of individual chemicals through a powder or slurry, using the principals of partition equilibrium.) Although the over-arching concepts are very similar, the modern GC’s column is now a very thin, coiled capillary tube. These fine quartz or fused silica tubes have only 0.1 to 0.53 millimeter internal diameters, but are cut to 12 to 100 meters in overall length! Modern capillary tube columns are internally coated with a thermally stable, high molecular weight polymer. This extremely thin polymer layer (0.1 – 10 thousandths of a millimeter) is referred to as the ‘Stationary Phase’.

A second common misconception comes from the word “Chromatography” itself. When you see ‘Chroma’ you might think ‘color’. When you see ‘-graphy’ you would normally assume there is some type of written or printed result. Just as the ‘column’ sub-component name has carried over from traditional separation techniques, so has the ‘chroma’ element. In the early days of thin layer chromatography (circa 1900), it was the actual colors of the various compounds in plant materials spread across the paper stationary phase which gave the Chromatography process its name.

Lastly, there isn’t a universal gas chromatograph for every compound. Some aspects of the sample to be tested must be known in advance, so that the right kind of GC is used. Different chemical groups need different columns, tailored to their properties. Certain volatile compounds need to be vaporized, and kept that way, meaning oven heating schedules must be selected for the best separation resolution. Most importantly, there are many different types of detector heads to match the appropriate selectivity of the test sample. Detector technologies include flame ionization, thermal conductivity, electron capture, photo-ionization, conductive, and so on… A majority of the detection technologies are dependent on steady state mass flow rates.

Timing is everything

As the various chemical compounds move through the capillary via the flow of inert gas—called the Mobile Phase—each will effectively ‘stick’ to the walls of the column at varying levels of adhesion and therefore will elute through the tube and into the detector head at different times. This happens regardless of the steady flow rate of the carrier gas, since the compounds all have a unique—and therefore identifiable—affinity to the stationary phase coating inside the capillary. All of the compounds make it through eventually; but it’s how fast they make it through that distinguishes one from another. Because of this, it is imperative for the carrier gas flow rate to be constant; otherwise flow rate would become a seriously disruptive variable to the detection of a particular chemical compound.

Imagine a sturdy wooden ramp in your backyard, used to roll different types of balls across a freshly cut patch of grass. Starting at the top of the ramp, a bowling ball rolls down, and across the yard. It’s barely slowed by the friction of the grass. A Bocce ball has a similar result, but doesn’t quite make it as far as the bowling ball. A soccer ball falls someplace in between the two. A whiffle ball hardly goes a few feet past the end of the ramp, and a ping pong ball is stopped within inches. Obviously, each ball has its own mass, diameter, angular momentum, rolling resistance, etc., but within reason, one could determine which ball is which, just by how far it rolled on the grass; once the norms were established. This assumes of course that the uniform grass surface (think: polymer coating in column) isn’t swapped out for a rocky dirt lot (a contaminated column), and that the fixed wooden ramp (a.k.a. the steady carrier gas flow rate) isn’t raised or lowered randomly during testing (unstable gas flow).

Minimizing the Variability of Flow

The effectiveness of a gas chromatograph relies heavily on stability and repeatability. Whether it be the method of injection of the sample, the computer controlled oven temperature profile, the use of a clean ‘blank’ (just ask any DUI lawyer about that one!), or the steady state flow of the carrier gas, the only variable in the process should be the sample itself.

Alicat Scientific, Inc. specializes in both precision mass flow control and high speed/high accuracy pressure control; each of which can be used to deliver exacting inert gas flows to your GC column. Even in low flow regimes, our mass flow controllers can provide stable flow from zero to full scale within tens of milliseconds. Each MFC has the ability to measure and control up to 98 default (common) gases and gas blends; changeable on-screen, or via digital control. No matter what inert carrier is being used for a particular test (N2, He, Ar, CO2), you can use the same Alicat MFC for each, so long as it is set to the gas being flowed.

If the GC uses a fixed orifice that requires stable pressure control, Alicat produces a wide range of electronic pressure controllers (both standard and OEM electronic pressure regulators) which can be custom tailored to just about any flow rate/pressure condition/speed, achieving the best result possible.

For verifying flows in a particular gas chromatography system, or to calibrate the gas delivery components within a GC, use one of our portable calibration flow meters to quickly establish proper carrier gas operation:

Our flow measurement technology has been used and trusted for over 25 years by some of the leading gas chromatograph manufacturers in the world.

Thermal dispersion is the Generation X of flow measurement technology; the 1960s and 70s saw the first thermal dispersion mass flow measurement technology, and it has since become a staple in the semiconductor industry. By measuring the transfer of heat between a heating element and a temperature sensor mounted parallel to gas flow direction on a bypass line, the mass flow of the gas in the line can be measured.

Thermal dispersion is the Generation X of flow measurement technology; the 1960s and 70s saw the first thermal dispersion mass flow measurement technology, and it has since become a staple in the semiconductor industry. By measuring the transfer of heat between a heating element and a temperature sensor mounted parallel to gas flow direction on a bypass line, the mass flow of the gas in the line can be measured. Through-flow constant temperature anemometry is a close cousin to thermal bypass technology; instead of a bypass, a heater and temperature sensor probe are inserted directly into the flow stream to measure the thermal dispersion through the flowing gas. A constant ΔT is maintained between the heater and sensor, and the difference in power required to maintain the ΔT at different flow rates is correlated with mass flow.

Through-flow constant temperature anemometry is a close cousin to thermal bypass technology; instead of a bypass, a heater and temperature sensor probe are inserted directly into the flow stream to measure the thermal dispersion through the flowing gas. A constant ΔT is maintained between the heater and sensor, and the difference in power required to maintain the ΔT at different flow rates is correlated with mass flow. These technologies are an application of thermal mass flow measurement in miniature chip form. MEMS and CMOS chips average the temperature change measured across a chip. The thermal load is created by a constant-power heater. Due to the size of the measurement element, chip flow devices can be very small and consume very little power. In contrast to through-flow constant temperature anemometry and thermal bypass technology, these tiny devices can have extraordinary response times when paired with a well-tuned control package, even as fast as 50 ms.

These technologies are an application of thermal mass flow measurement in miniature chip form. MEMS and CMOS chips average the temperature change measured across a chip. The thermal load is created by a constant-power heater. Due to the size of the measurement element, chip flow devices can be very small and consume very little power. In contrast to through-flow constant temperature anemometry and thermal bypass technology, these tiny devices can have extraordinary response times when paired with a well-tuned control package, even as fast as 50 ms. Laminar flow differential pressure technology uses a different physical parameter to fill a need in the industrial and the analytical worlds. Pressure sensors are built on diaphragms that are incredibly sensitive to changes, making them among the fastest sensors available. By laminarizing flow,

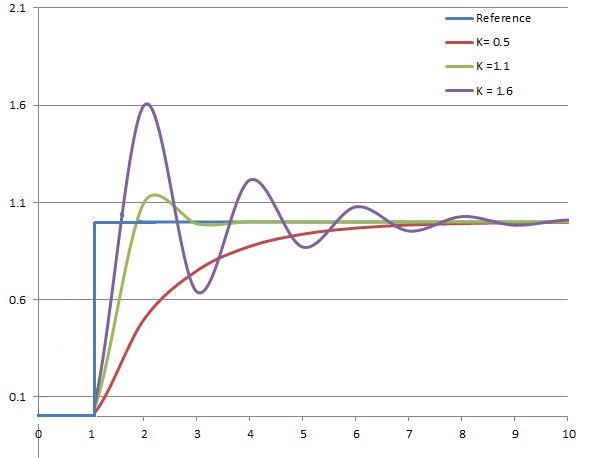

Laminar flow differential pressure technology uses a different physical parameter to fill a need in the industrial and the analytical worlds. Pressure sensors are built on diaphragms that are incredibly sensitive to changes, making them among the fastest sensors available. By laminarizing flow,